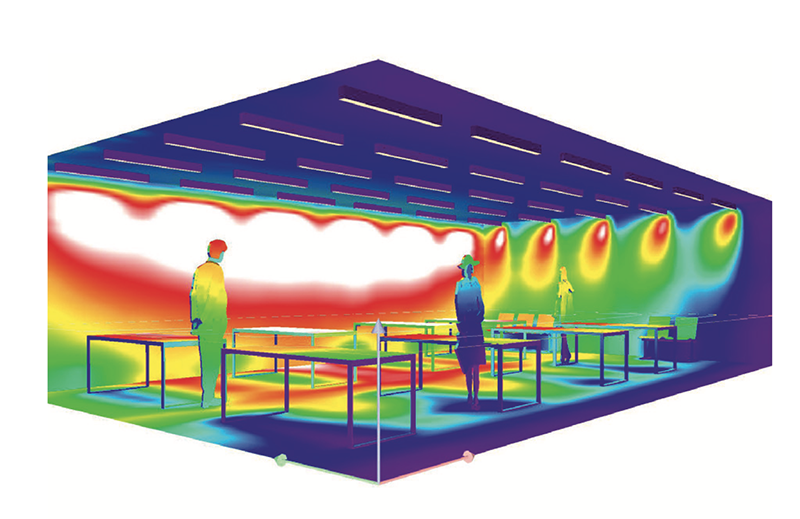

We produce fittings for use within all kinds of public spaces such as offices, banks, shops, shopping centres, etc., and outdoor fittings designed to illuminate buildings, car-parks, petrol stations and parks.

With the skilful combination of modern design, functionality and excellent lighting parameters we are able to compete with the biggest world leaders in the field of lighting.

Imperial produces fittings under its own brand name, which can be found in the Company’s catalogues. It also carries out production for many global producers under their brand names. We work with several university research centers in the country and abroad.

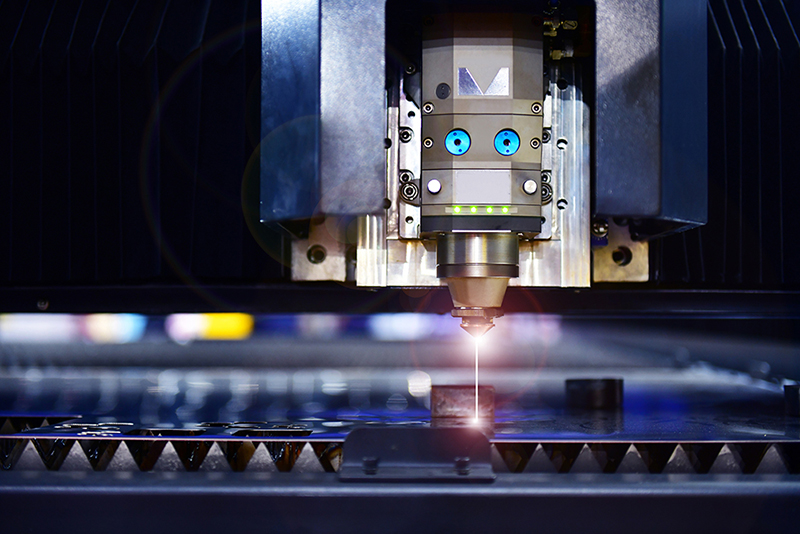

At the same time, we produce lighting fixtures according to the customer’s individual ideas: it follows the ideology saying that if in your imagination there is a vision of a fitting, come and we will make it come true. The excellent, professional, highly qualified staff ensures that Imperial products are of the highest quality, in line with current trends, safe and unique in style.